In today's evolving business landscape, companies are constantly seeking strategic ways to enhance their performance and profitability. One essential avenue for achieving this goal is through supply chain partnership. By fostering strong relationships between various stakeholders across the supply chain, organizations can unlock significant value and achieve a competitive advantage.

Utilizing collaborative practices enables businesses to optimize their operations, reduce costs, improve delivery times, and increase customer satisfaction. Through shared data, visibility, and planning, supply chain partners can responsibly address issues and predict future demands. This collaborative approach not only improves individual organizations but also contributes to the overall robustness of the supply chain ecosystem.

- Enhanced communication and information sharing

- Decreased lead times and delivery costs

- Maximized inventory control

- Enhanced customer satisfaction through consistent deliveries

Moreover, supply chain collaboration fosters a culture of transparency among stakeholders, leading to lasting partnerships and mutual success. By embracing collaborative practices, organizations can harness the full potential of their supply chains and drive sustainable growth in today's globalized marketplace.

Real-World Examples of Successful Supply Chain Collaboration

Collaboration within supply chains has become increasingly crucial for companies seeking to optimize efficiency and achieve sustainable growth. Numerous examples demonstrate the profound benefits of collaborative practices across various industries. For instance, in the automotive sector, manufacturers like Ford have implemented robust collaboration programs with their suppliers, resulting in improved production planning, reduced lead times, and enhanced quality control.

Similarly, in the consumer goods industry, Procter & Gamble has fostered strong connections with its retailers through data-sharing initiatives and joint forecasting efforts, leading to increased profitability. Additionally, in the healthcare sector, pharmaceutical companies often collaborate with research institutions and hospitals to accelerate drug development and bring life-saving treatments to patients more rapidly.

Building a Robust Supply Chain Collaboration Strategy

In today's dynamic business environment, organizations are increasingly recognizing the value of strong supply chain collaboration. Developing a collaborative strategy can go to the website substantially enhance operational efficiency, reduce costs, and improve customer satisfaction. To achieve this, companies must foster strong partnerships with their suppliers. This involves shared information throughout the supply chain, harnessing technology to streamline processes, and continuously assessing performance.

- Cooperation is key to success in today's global marketplace.

- Automation can play a crucial role in facilitating collaboration.

- Data sharing is essential for effective decision-making.

Clarifying Supply Chain Collaboration: A Comprehensive Guide

Supply chain coordination is a crucial element in achieving efficiency within today's dynamic global marketplace. It involves the strategic interaction of companies across various stages of the supply chain, from raw material sourcing to final product delivery. This collaborative approach aims to streamline processes, reduce costs, and ultimately deliver a more efficient customer experience.

- Cooperation within the supply chain can lead to enhanced inventory control.

- Effective dialog is essential for fruitful supply chain coordination.

- Information sharing among suppliers and end-users is a hallmark of strong supply chain networks.

Unveiling the Strength of Shared Transparency in Supply Chain Networks

In today's dynamic and interconnected global market, effective/successful/robust supply chain management/operation/execution hinges on collaboration. Sharing/Providing access to/Granting visibility into critical data across all levels/tiers/stages of the supply chain empowers stakeholders to make informed/timely/strategic decisions that optimize efficiency and reduce/minimize/lower risks. When every participant has a clear and consistent/accurate/comprehensive view of inventory, production schedules, and potential disruptions/challenges/bottlenecks, it fosters/it enables/it facilitates real-time collaboration/coordination/alignment. This shared visibility cultivates/builds/strengthens trust among partners, leading to improved/enhanced/optimized communication, proactive/anticipatory/preventative problem-solving, and ultimately, a more resilient/flexible/adaptable supply chain.

Driving Efficiency and Innovation through Collaborative Supply Chains

In today's dynamic business landscape, companies are increasingly recognizing the criticality of collaborative supply chains in gaining a tactical advantage. By fostering robust partnerships with suppliers and other stakeholders, businesses can harness new levels of optimization. This cooperation allows for instantaneous data sharing, streamlined processes, and refined decision-making. Moreover, collaborative supply chains encourage innovation by stimulating the sharing of ideas and best practices across the entire value chain.

- Exploiting technology platforms to enhance communication and clarity

- Formulating shared goals and metrics to synchronize supply chain efforts

- Nurturing a culture of trust and partnership among all stakeholders

Through these operational initiatives, businesses can revamp their supply chains into powerful engines of efficiency and innovation.

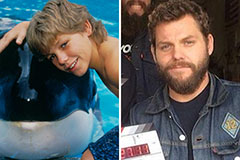

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Jeremy Miller Then & Now!

Jeremy Miller Then & Now! David Faustino Then & Now!

David Faustino Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!